Innovation Competition Gesünder.In.NRW

Small and medium-sized enterprises (SMEs) can often only develop new, innovative, sustainable, and marketable products, services, and processes in cooperation with other companies, universities, and research institutions. The innovation competitions of the ERDF/JTF Programme NRW 2021–2027 therefore focus on collaborative projects involving SMEs, large companies, and research institutions that are aligned with one of the six innovation fields of the Regional Innovation Strategy of the state of North Rhine-Westphalia.

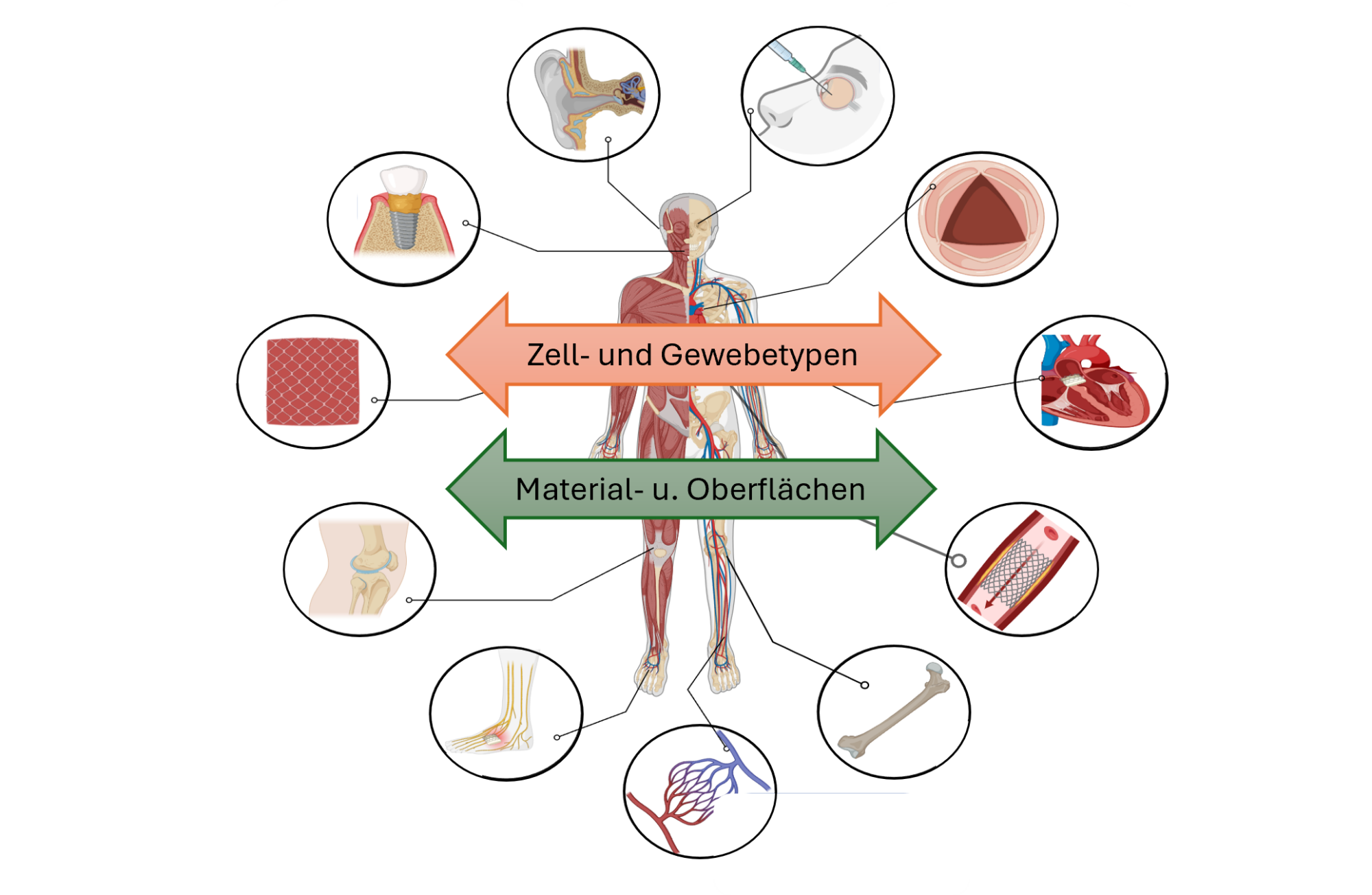

The innovation field “Innovative Medicine, Health, and Life Sciences” covers knowledge- and research-intensive topics from medicine, particularly cutting-edge medicine, medical technology, life sciences, nutritional sciences, and pharmacy. Innovative medicine, through the development of new procedures, techniques, and methods, acts as a driver of innovation for science-driven biomedical research.

North Rhine-Westphalia boasts a highly efficient scientific and research landscape. The measure is intended to help accelerate the transfer of new ideas and concepts from science and industry into innovative, market-ready, and sustainable products and services. Solutions for prevention, novel treatment options, and therapy forms are a thematic priority, with digital technologies and biotechnology playing a particularly important role as key and cross-sectional technologies. The aim of the state of North Rhine-Westphalia is to strengthen and further expand its leading role in the digitalization of the healthcare sector. Sustainable innovations in biotechnology offer value-creation-oriented solutions for all areas that are the focus of this competition.

Research Problem

The prevalence of bone metabolism disorders such as osteoporosis and other bone diseases like osteoarthritis is increasing significantly due to rising life expectancy in Western societies. Although current osteoporosis treatments slow down the progression of bone fragility, the number of fracture treatments continues to rise. Likewise, in age-related joint degeneration, the number of joint prostheses being implanted is steadily increasing. The same applies to the absolute numbers of required revision surgeries in endoprosthetics. These become necessary due to premature loosening, which leads to an enormous burden on patients, reduces patient well-being, and places significant cost pressure on the healthcare system.

In this context, there is a need to develop better, personalized drugs against osteoporosis and innovative surface modifications for artificial joint components that enable improved integration and anchoring of the artificial components in patients’ bones. This is particularly important for patients suffering from osteoporosis.

The development of new drugs and bone-integrating surface modifications of implant materials is still largely based on experimental animal studies, which are often unsuitable. Growing and persistent ethical concerns in society regarding the purpose of such studies, as well as the very limited translatability of results from animals to humans in clinical applications, are increasing the pressure to develop alternative and predictive preclinical models based on human cells and tissues.

In line with the 3R initiatives aimed at reducing animal suffering and, where possible, avoiding animal testing, there is currently a growing need for human in vitro bone cell interaction models/assays (KIAMA). These enable preclinical, regulatory-compliant ((EU) 2017/745 (MDR); IVDR 2017/746) high-throughput testing of drugs, biomaterials, and surface modifications using patient-specific cells.

To address this challenge, the Department of Experimental Surgery at Ruhr University Bochum (ExpChirRUB) has further developed a new, previously unique surface coating called OsteoMimic, which mimics the native bone matrix. This coating enables homogeneous, bioactive surface functionalization of substrates or test specimens of any scaffold geometry/topography.

The Innovation

The central innovation of the project KlAssE-Integration lies in the joint development and validation of a regulatory-compliant, preclinical, predictive, and customizable in vitro bone cell interaction model/assay (KIAMA) for the testing of solid biomaterials and their surface modifications for applications in human long bones.

To achieve this innovation, the following novel sub-aspects will be pursued:

Laser-based high-speed cell sorting of osteoclasts (hOCs): Homogenization of heterogeneous populations according to cell size and morphology under regulatory-relevant laboratory conditions.

Increased efficiency of the OsteoMimic KIAMA through the use of homogeneous hOC cultures.

Robust assay for evaluating the influence of contaminants from HydroJet processing of high-performance implant materials in microtiter plates (2D-KIAMA).

First-time application of a miniaturized HydroJet process to improve bone interaction through surface structuring of implant materials, followed by bioevaluation using KIAMA.

3D-KIAMA

Innovation needs strong PARTNERSHIPS