The abrasive waterjet technology (AWT) offers great potential for conventionally hard-to-machine materials and is already being used successfully in industrial applications for cutting these materials. The process principle is based on a high-speed water jet to which fine abrasive particles are added. This allows for the flexible machining of almost all materials and material combinations, making it many times more productive compared to other alternatives such as laser cutting, and without causing thermally induced changes to the material properties.

The engineers at Fraunhofer IPT have advanced and refined the foundational principles of water jet milling, pushing the boundaries of this innovative technology. Their research has led to significant improvements, making water jet milling even more precise and efficient for potential industrial applications.

Follow this link to learn more.

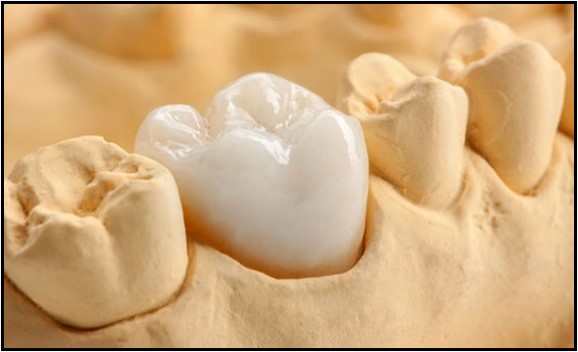

In a recent collaboration with industry partners, we have explored the integration of water jet milling for the direct processing of high-strength dental ceramics. Currently, the complex manufacturing processes drive up costs for end consumers. Using water jet technology to produce dental crowns could dramatically reduce production costs.